Page 13 - Maureen Visagé

P. 13

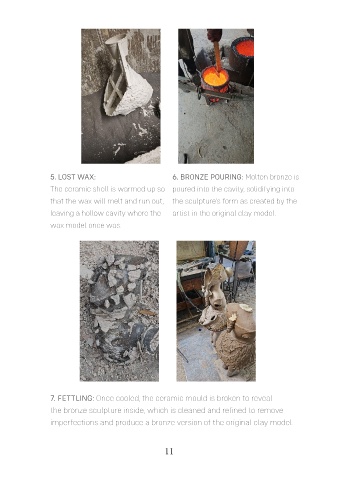

2. SILICONE MOULD: A silicone mould is made around the clay 5. LOST WAX: 6. BRONZE POURING: Molten bronze is

model in order to produce wax replicas. The mould is used for a The ceramic shell is warmed up so poured into the cavity, solidifying into

pre-determined limited number of reproductions, ensuring the that the wax will melt and run out, the sculpture's form as created by the

exclusivity of each edition. After which the mould is destroyed. leaving a hollow cavity where the artist in the original clay model.

wax model once was.

3. WAX CASTING: 4. CERAMIC SHELL: The

Melted wax is poured wax model is coated in liquid

7. FETTLING: Once cooled, the ceramic mould is broken to reveal

into the mould to form ceramic slip, a slow process,

the bronze sculpture inside, which is cleaned and refined to remove

a hollow replica of the dipping it layer by layer, until

imperfections and produce a bronze version of the original clay model.

original sculpture. it hardens into a robust shell.

10 11